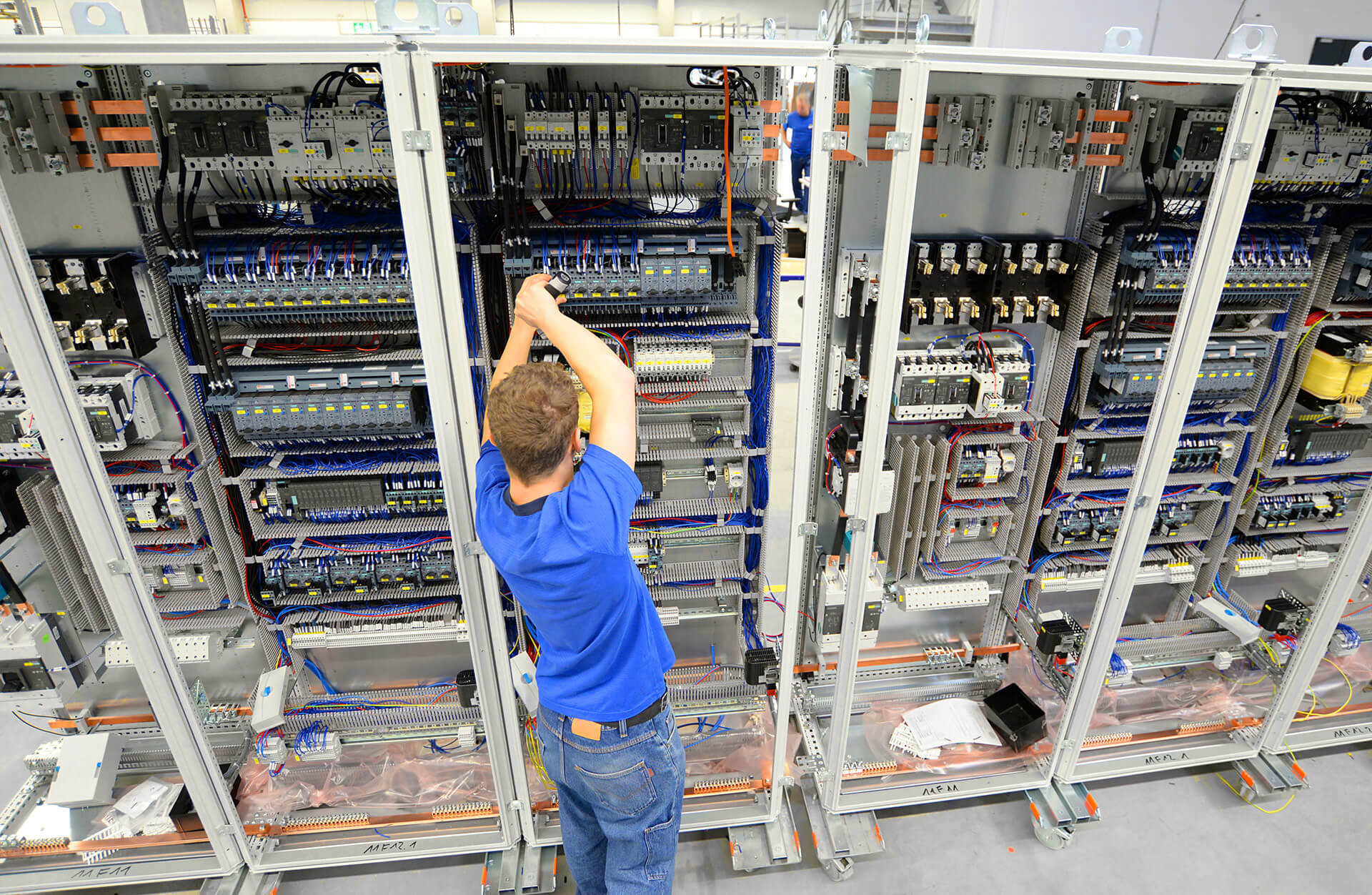

In the hospital environment, electrical panels and their efficient management are an essential element to guarantee the correct functioning of critical medical equipment, emergency systems and the safety of patients and staff. These are key nodes for distributing and controlling electrical energy in hospital facilities.

What are electrical panels in hospitals?

Also known as electrical panels or distribution panels, they are devices that concentrate and distribute electrical energy from the main electrical network to different areas of a building.

In the hospital context, these pictures are vital, especially in critical situations such as medical emergencies and surgeries. In fact, they represent a critical and necessary component in all hospital infrastructures because they allow the distribution of energy in each consumption line, the safety of the facilities and the continuity of supply to be guaranteed efficiently in the production processes.

Principal functions

Electrical panels in hospitals have four basic functions:

1. Power Distribution

Electrical panels distribute electrical power safely and efficiently through various circuits that power specific areas of the hospital, such as operating rooms, intensive care rooms, and diagnostic areas. At the same time, they protect the lines that feed the secondary electrical panels that are sized to protect the production processes at their outputs.

2. Protection, supervision, control and safety

They incorporate protection devices, such as circuit breakers and fuses, to prevent short circuits, overloads and other adverse electrical events that could affect the integrity of medical equipment and the safety of people. In addition, the monitoring and control of electrical panels through digital systems makes it easier to have detailed information on the status of switches and circuits anywhere and everywhere.

3. Emergency management

In critical situations they allow uninterruptible power supply systems (UPS) and backup generators to be activated to ensure that the most vulnerable areas of the hospital maintain their power supply, even during power outages.

4. Continuity of supply

They guarantee energy through the optimal design and choice of the different protections linked in series so that they have selective coordination, known as “electrical selectivity”. Thus, in the event of a possible defect, the closest protection would be bypassed, isolating the fault, without affecting the header switch or the rest of the electrical lines in the installation.

Types of electrical panels in hospitals

Given their vital work, manufacturers have been working for years on increasingly complete, improved and specialized solutions in specific situations in which their installation in hospitals and health centers is necessary.

For this reason, there are different types of specialized panels, depending on the degree of demand and the continuity of supply required by the installation and the critical processes it protects. The most common are:

Main panels (MDB)

Distribute power from the hospital’s main electrical network to subpanels and secondary circuits.

Subpanels (SDB)

Located in specific areas, they receive power from the main panel and distribute it to devices and equipment in those areas.

Emergency panels

Designed to ensure the continuity of the electrical supply during power outages, these panels prioritize the power of essential equipment in critical situations.

There are also two other types of electrical panels that are essential in health centers and for medical equipment.

On the one hand, there are compartmentalized panels (CCMs), or motor control panels, designed for high output powers and compartmentalized, allowing load sectioning. They are essential because they operate in centers where activity cannot be paralyzed in the event of a possible defect, repair or maintenance of one of their output lines, guaranteeing continuity of supply.

For their part, the automation and process control panels internally dominate the processes that communicate with the outside. They are designed to collect real-time data from sensors and devices located in the process or system being monitored. Then, they use this data to automatically control and regulate the process variables, whether temperatures, pressure, flow, speed…

Key components

The most relevant elements that we can find in electrical panels are automatic switches, fuses and energy meters.

Circuit breakers protect against overloads and short circuits by automatically disconnecting the affected circuit. In this case we differentiate between a header switch that protects all the lines and allows all energy to be disconnected from the electrical system in the event of a defect, emergency or to perform maintenance, and differential switches, also called ground connection switches, its function is to protect against leakage or current leakage to ground.

Fuses offer protection against excessive currents and blow to interrupt electrical flow in the event of an overload.

While energy meters allow you to monitor electricity consumption and optimize the hospital’s energy efficiency. They give the parameters of electrical values such as voltages, intensities, active and reactive energy, power, harmonics… being able to track electrical consumption in different circuits or areas and carrying out efficient energy management.

Current standards and certifications

The regulations on electrical panels in Spain, for the construction of electrical panels, are established in the Low Voltage Electrotechnical Regulations (REBT).

This is the legal framework that delimits the safety and quality conditions for hospital electrical installations in Spain and where the requirements for the construction and design of electrical panels are indicated, including the types of materials, protections, circuit distribution, wiring diagrams. connection, etc.

Other standards to take into account when constructing electrical panels are:

- IEC 60364

International standard that addresses low voltage electrical installation, applicable in many countries.

- Standard UNE-EN 61439

The general requirements for low voltage switching and control assemblies, including electrical panels.

- Standard UNE-EN 60947

Covers the maneuvering, protection and control devices used in electrical panels, such as automatic switches, differential switches, contactors, etc.

- ITC-BT 16, 17,19 and 20.

These are technical instructions for the connection of conductors and cables, the selection and assembly of protection and switching devices or surge protection systems in electrical panels.

In conclusion, electrical panels are the most important element of hospital electrical infrastructure.

This is a crucial element to guarantee the safety, reliability and efficiency of electrical infrastructure in medical environments. That is why it is always necessary to comply with regulations and certifications to ensure that these systems operate optimally, thus contributing to the well-being of patients and the effective functioning of medical staff.

Furthermore, the design, installation and maintenance of electrical panels in hospitals must be carried out with a rigorous approach and in accordance with current regulations to guarantee the quality and safety of the electrical supply.

If you need to renew the electrical infrastructure of a health center, or want more information, do not hesitate to contact us. At ETKHO we are a team of engineers with more than 30 years of experience, specialized in engineering and electrical solutions for hospitals.