Industry 4.0 represents a before and after in the way of working, in the use of resources and in the optimisation of time. That is why it offers a whole series of benefits to any sector, and especially to the one that concerns us, the healthcare sector, and its relationship with the energy sector.

Why?

Because it is a key element in adapting to market trends, boosting competitiveness and addressing the energy transition towards cleaner and more sustainable energy. It is also for the management of the electricity system in each hospital.

To find out more about this new Industry 4.0 and its role in healthcare, in this post we look at its current and future role, its characteristics and what it can bring to hospitals.

What is Industry 4.0?

Industry 4.0 is the organisation of companies whose aim is to achieve the concept of an intelligent place, capable of adapting much better to the needs and processes of production and its operation. It is known as the fourth industrial revolution, the cyber-industry of the future or smart industry.

In the field of healthcare, the digital transformation of the sector has accelerated significantly in the last five years. Technologies such as artificial intelligence, robotics, the Internet of Things (IoT), big data and quantum computing are beginning to show their true power, and to be considered necessary investments.

“The commitment to Industry 4.0 in healthcare is based on the objective of increasing the quality of medical care and hospital processes through digital transformation.”

This smart hospital has digital solutions to be more efficient and offer better patient care in reference to the infrastructure found within a hospital, clinical office or laboratory, among others.

New functions with 4.0 technology in the electrical system

Until now, the presence of the medical isolation monitor alone continuously monitored the isolation resistance of medical IT systems. With Industry 4.0, we are able to digitally and completely check the status of the electrical system when it is equipped with 4.0 device connection functions.

What new functions does Industry 4.0 bring to the electrical system?

- Collecting data: With automated 4.0 systems, you can integrate real-time signals and trends of the insulation level in each of the monitors installed in your hospital from each operating theatre and intensive care unit areas.

- Automatically identify faults: In addition to alarms and alarm repeaters, to identify the source of the fault, automatic devices will detect and report immediately any loss of insulation, power line disturbance, deterioration, etc.

- Current monitoring: Knowing the actual consumption of each circuit, in times of skyrocketing energy expenditure, is essential. By connecting the equipment to the isolation boards, consumption can be easily identified in the event of mechanical problems and a possible fault can be identified at an early stage.

- Real-time monitoring: Industry 4.0 and its devices make it possible to have displays, whether in the operating theatre, plant or other critical areas, that transmit information about the status of electrical systems in real time.

A decisive role in the energy transition

What role does Industry 4.0 have in the energy transition?

A very important one, without a doubt. Thanks to this innovative model, incentives for consumption that are not energy efficient are eliminated, own resources are used to a greater extent, and the consumer is at the centre of the energy system.

In other words: the fourth industrial revolution, with cybernetic systems, robots, digitalisation, Big Data, the energy transition and cybersecurity, will help considerably to reduce energy costs in hospitals and to develop more sustainable and efficient models of energy consumption and production.

Benefits of Healthcare 4.0

Smart hospitals 4.0 enjoy numerous benefits, all of which revolve around increasing the quality of medical care.

The philosophy of creating modern hospitals built on an ICT environment and interconnected tools, through new functionalities, facilitates the work of doctors, reduces healthcare costs and improves the patient experience.

Other advantages include:

- Enabling technological development within hospitals, achieving a high degree of customisation to meet customer requests.

- Optimisation in decision-making thanks to the availability of accurate, real-time information, favouring the efficient use of resources and increased productivity.

- Reducing costs by improving the efficiency of the use of hospital equipment and the economic return on the investment made, even in the short term, by improving the energy and electrical area of hospitals, perfecting the facilities and electrical equipment.

- Mitigate risks, make a more accurate diagnosis and improve operations and workflows.

- Improve sustainability and the environment by reducing and improving the energy consumption of the systems involved in hospital operations.

- Refine prediction with machine learning models, which collect all the data necessary to create predictive algorithms.

The power system & digital world

The patient’s life is in the hands of both the medical staff and the hospital engineer, architect, etc. who design the hospital spaces. And one of the most important parts of this infrastructure is the hospital electrical system.

What Industry 4.0 brings to this field, which is the one that most concerns us at Etkho, is digitisation and access to relevant data for effective decision-making, to ensure optimal working conditions in operating theatres and any other healthcare area, etc.

And especially for the medical team to work and operate with a safe electrical system that never switches off and protects the patient and medical staff. For this, there is the isolated electrical system. In recent years, this has been supported by the evolutionary support of Industry 4.0, digital transformation and digitisation, to take it a step further.

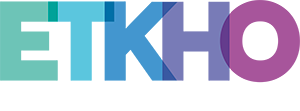

Basic elements of electrical safety

It is worth remembering that the different equipment and elements that will help us to keep the ICU, operating theatres, resuscitation areas and other rooms electrically safe are:

- Earthing connections, hospital earthing panels and electrical sockets.

- Batteries and isolation transformers.

- IT power supply systems, to detect electrical earth faults and locate them easily and quickly.

- Isolation monitor and its multi-repeater, to continuously monitor the insulation resistance of medical IT systems.

- Uninterruptible power supply systems, enabling emergency power supply of specific loads.

- Alarm repeater.

Digital twins, data and algorithms in Industry 4.0 in the healthcare sector

Patient centricity, data-driven and value-based medicine are the main characteristics of Hospital 4.0. And that is something that can be seen in those centres that already have a more effective management thanks to machine algorithms.

In this sense, the project Hospitals 4.0 – Machine learning for a more effective management, in which the Electrical Drives and Industrial Applications Research Group (MCIA) of the Universitat Politècnica de Catalunya – BarcelonaTech (UPC) participates, aims to build a digital twin that allows monitoring, visualising and managing the maintenance status of hospital equipment.

In other words: a digital twin that will allow anticipation and optimisation of resources thanks to the accurate representation of the performance of a real hospital environment in a simulated scenario.

Improving your hospital’s electrical system

In short, Industry 4.0 is all about the digital transformation of the isolated electrical system.

For more information about new 4.0 technologies for hospitals or about ETKHO’s digital transformation solution, please do not hesitate to contact us.